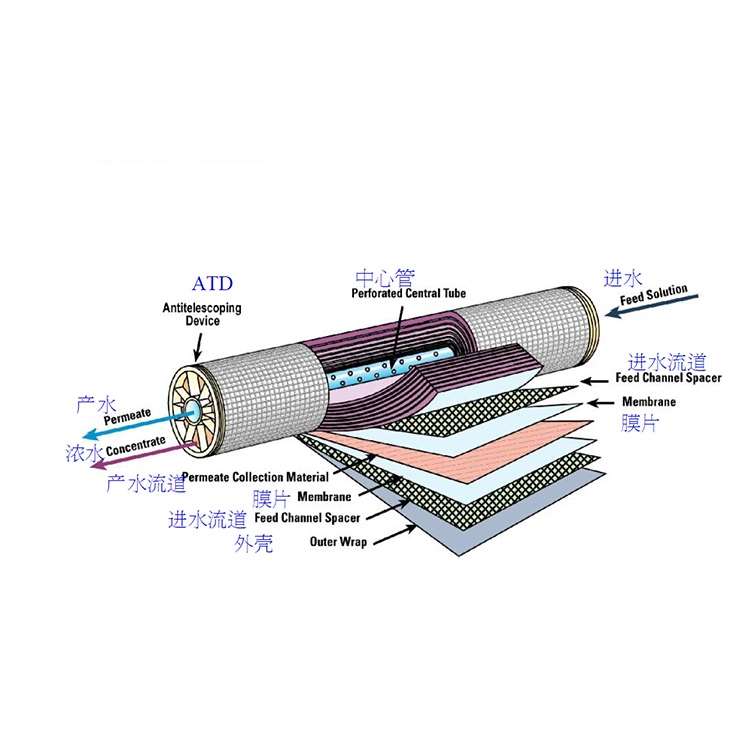

Inorganic ceramic membrane is a precision ceramic membrane filtration material with porous structure, which is sintered at high temperature by using the support body (titanium dioxide, alumina) as the support layer and the active separation layer (titanium dioxide + zirconia) as the film layer. The filtration method is “cross-flow filtration” : driven by pressure, the raw material liquid flows at high speed in the membrane tube, the permeating liquid containing small molecular components passes vertically through the membrane along the inner wall of the membrane tube, and the turbidized concentrated liquid containing large molecular components is trapped by the membrane, so as to achieve the purpose of separation, concentration and purification of the material liquid.

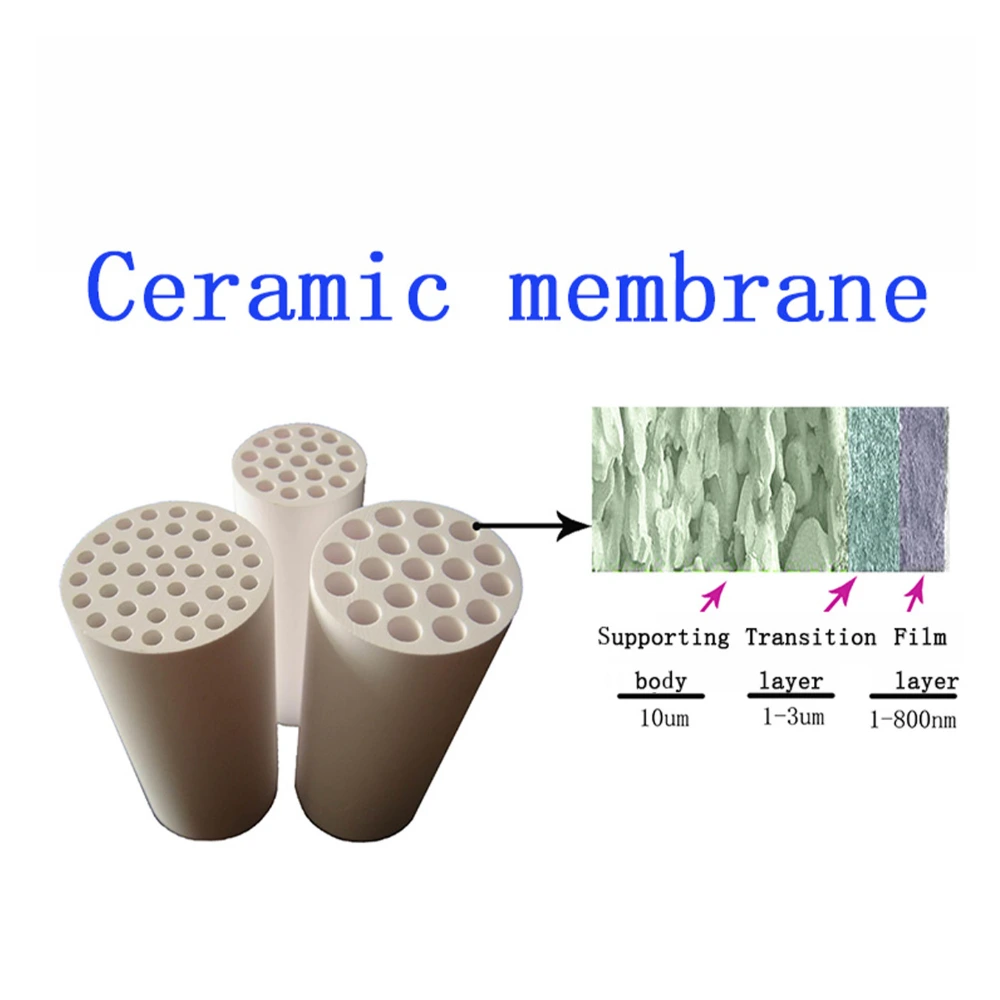

The structure of ceramic film is often sandwich: support layer, transition layer, film layer. The pore size of the supporting layer is generally 1~20μm, and the porosity is 30%~65%, which is used to increase the mechanical strength of the film. The pore size of the transition layer is smaller than that of the support layer, and its function is to prevent the penetration of particles into the porous support layer during the preparation of the film layer. The thickness is about 20~60μm, and the porosity is 30%~40%. The pore size of the membrane ranges from 4nm to 10μm, and the thickness is about 3~10μm. The porosity is 40%~55%. The pore size distribution of the whole membrane gradually decreases from the support layer to the membrane layer, forming an asymmetric distribution.

Inorganic ceramic membrane is a precision ceramic membrane filtration material with porous structure, which is sintered at high temperature by using the support body (titanium dioxide, alumina) as the support layer and the active separation layer (titanium dioxide + zirconia) as the film layer. The filtration method is "cross-flow filtration" : driven by pressure, the raw material liquid flows at high speed in the membrane tube, the permeating liquid containing small molecular components passes vertically through the membrane along the inner wall of the membrane tube, and the turbidized concentrated liquid containing large molecular components is trapped by the membrane, so as to achieve the purpose of separation, concentration and purification of the material liquid.