Industrialized ceramic membrane devices include three major categories: ceramic microfiltration membrane equipment, ceramic ultrafiltration membrane equipment, and ceramic composite membrane equipment. The industrial application of this series of equipment has been very successful. This series of devices can replace traditional clarification filtration, sterilization filtration, separation and partial concentration processes. The difference from small ceramic membrane experimental equipment lies in the processing capacity. It is mainly applied in large-scale industrial production, and the specifications and models are customized according to requirements.

Based on our company's many years of experience in membrane engineering applications, our ceramic membrane separation technology and equipment have won the recognition and trust of customers with their superior cost performance. It has been widely applied in food and beverage, biopharmaceuticals, plant extraction, light industry and chemical engineering, environmental protection water treatment, etc., and has also created high value for customers.

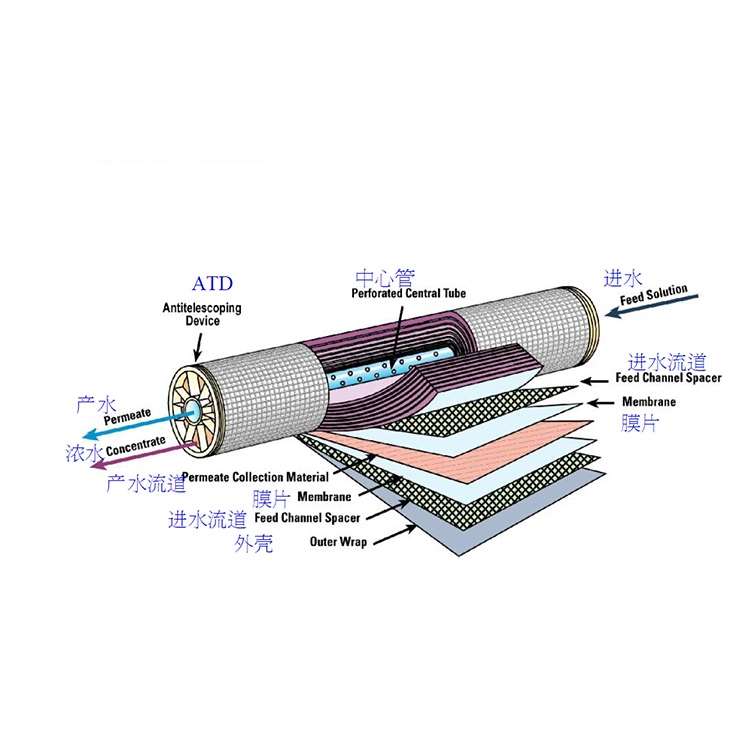

Ceramic membrane element is made from alumina and zirconia which is an asymmetric membrane structure with multi-channel tubular shape. The pore is on the channel. Driven by operation pressure, the liquid is running in the membrane. The part less than pore size is permeation, the part lager than pore size is concentrated liquid, so as to achieve the separation, concentration and purification purposes.